ADVANCED PACKAGING EQUIPMENT

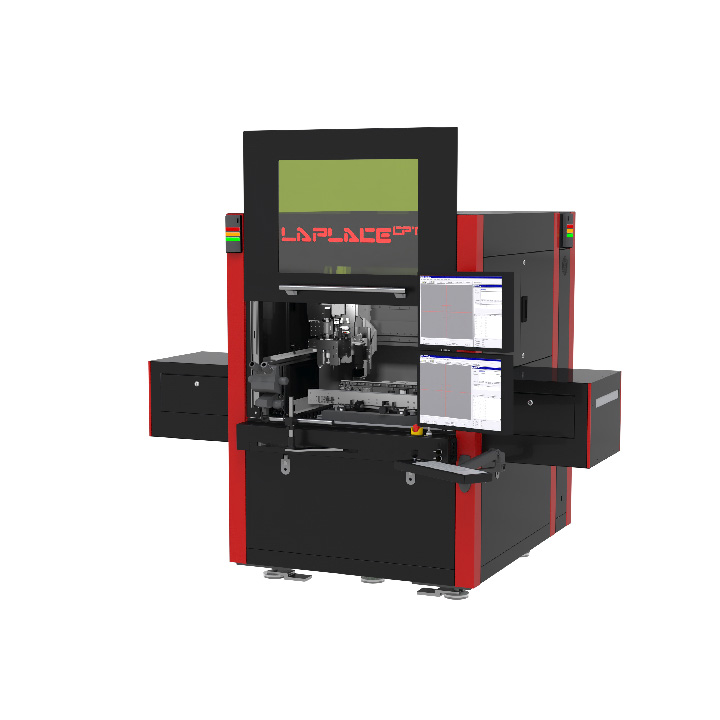

LaPlace – CPT

Laser Bonding System (LAB) with Compression Bonding and Laser Assisted Reflow.

SB² – USP

Highly flexible laser soldering and assembly platform for SMT components, especially for high-volume production in the automotive industry.

SB² – Jet

SB²-Jet is the machine with the highest placement precision and smallest solder ball capability.

SB² – Compact

SB²-Compact machine is the SB² entry point for high volume production with highly flexible and ultra-compact workstation.

Ultra – SB²

Ultra-SB2 is a fully automated solder bumping equipment integrating flux printing, ball placement, 2D inspection and wafer level rework.

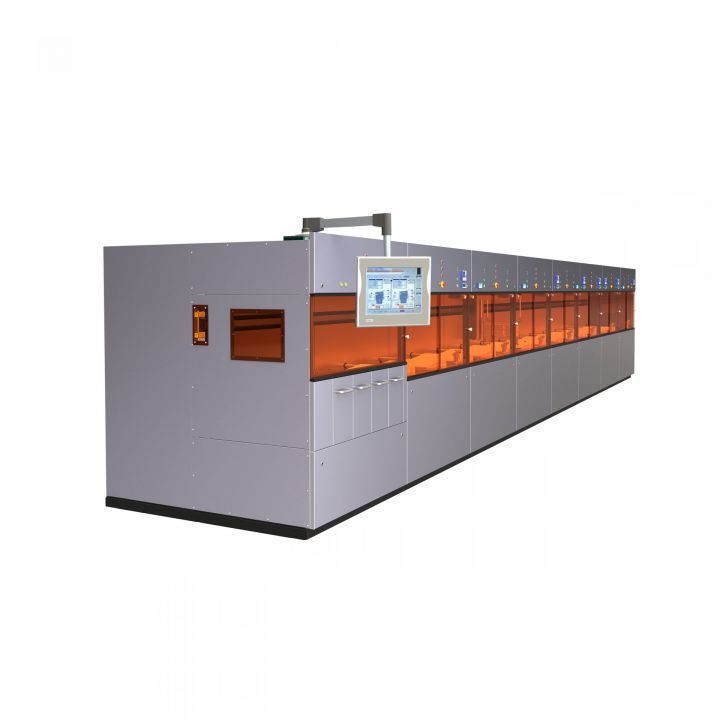

PacLine

The PacLine 300 A50 is a fully automated machine for electroless deposition of Ni/Au, NiPd or NiPdAu bumps on semiconductor wafers.

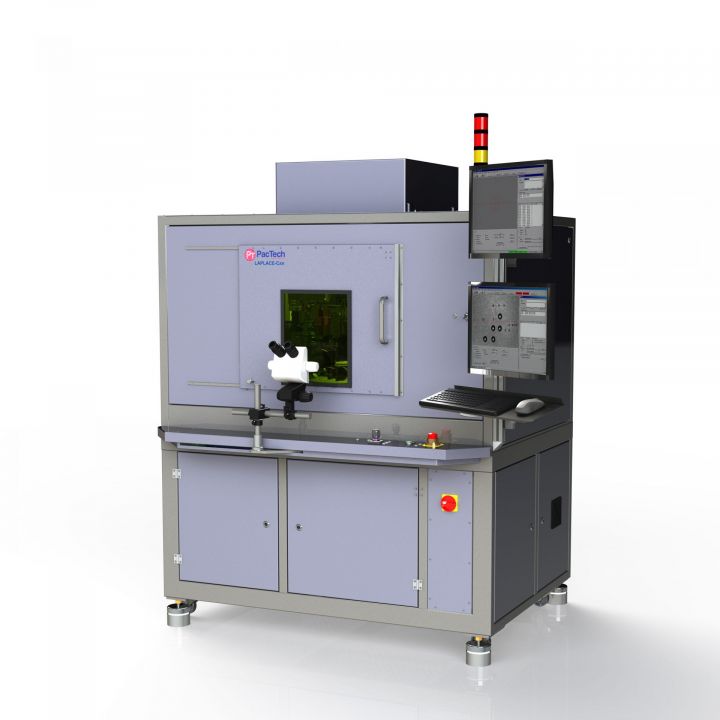

LaPlace – Can

Ultra-Fine-Pitch Cantilever Assembly and Laser Bonding for Wafer Probe Cards with optional Rework Capability.

LaPlace – HT

The LaPlace-HT is an automatic Laser Soldering machine for assembly of e.g. Schottky Diodes and Bypass Diodes – especially for solar cell modules.

LaPlace – VC

The LaPlace-VC laser bonder is a system for the vertical attachment of chips or similar devices loaded into the machine in waffle packs.

SB² – WB

SB²-WB is a combination of PacTech’s unique solder ball jetting machines with a wire feeding mechanism to perform wiring process.

LaPlace – FC

The LaPlace-System provides an integrated solution for flip chip assembly for laser assisted soldering, ACF and NCP interconnections.

SB² – SMs Quantum

SB²-SMs Quantum is highly recommended solution for high volume production. It achieves high throughput with dual loading station/drawer system that realize continuous production.

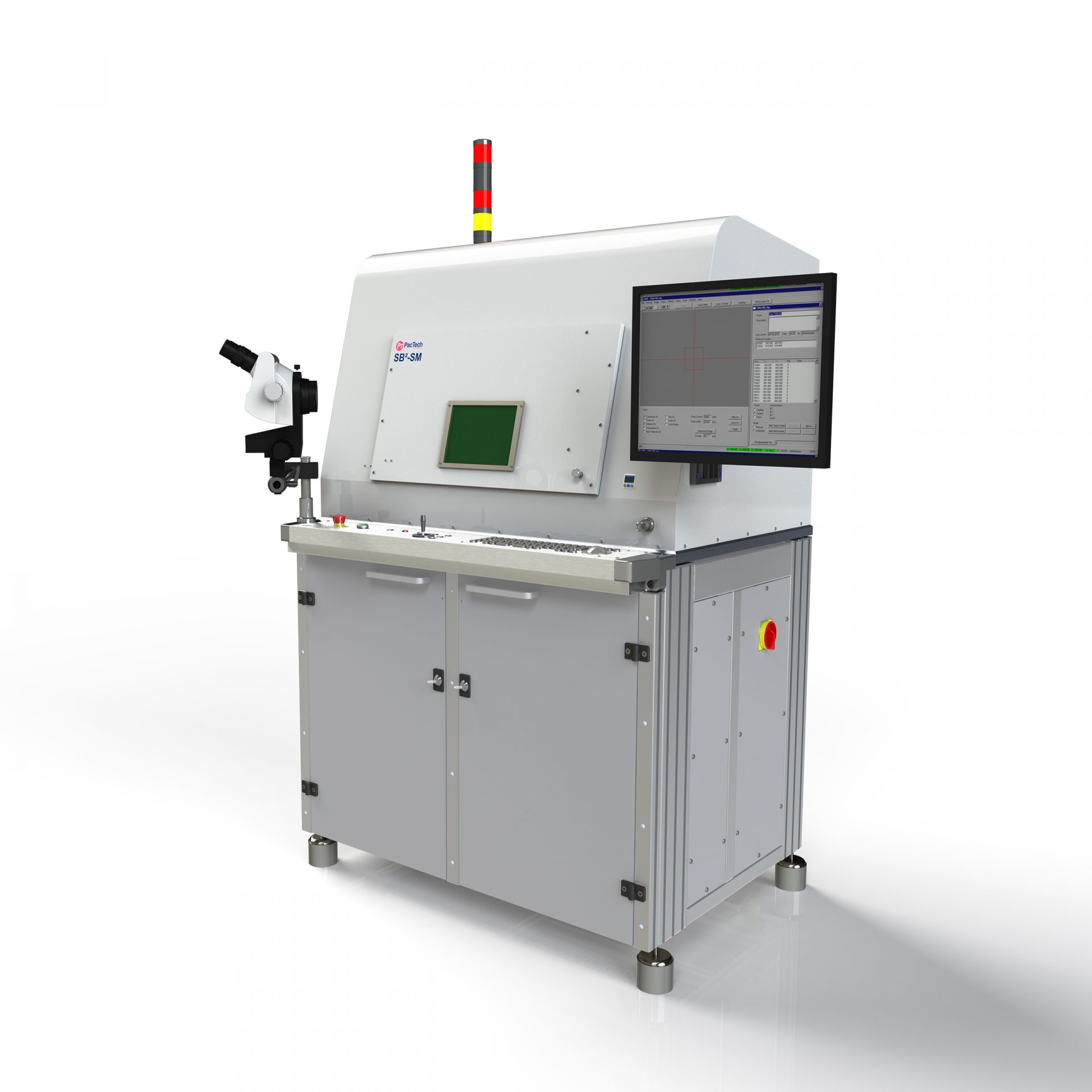

SB² – SM

The SB2-SM is a machine for prototyping and small volume production that has wider working area than the SB2-M and more optional features.