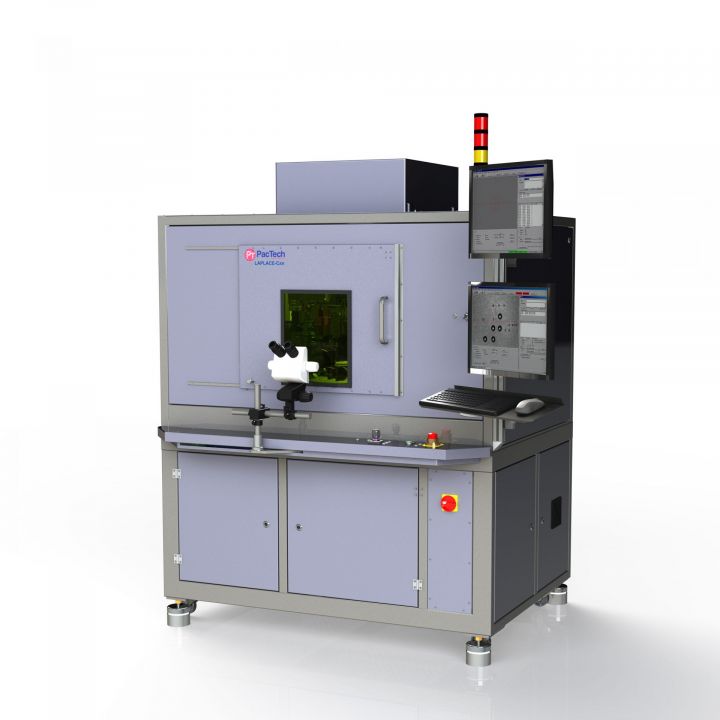

当社のレーザーはんだ付け技術は、クリーンで正確かつ柔軟性に富んでいます。独自のボールハンドリング機構により、単一のはんだボールをキャピラリー内に供給し、レーザービームの熱エネルギーではんだボールを溶かします。溶融したはんだボールを任意の位置に付着させることで、即座にリフローを完了ことができます。融点の異なる様々なはんだ合金にも対応しており、基本的にフラックスを必要としないプロセスなため、クリーンな作業が可能です。

また、レーザーによる局所的な加熱と極短時間のリフローにより、接合面以外の部分にかかる熱ストレスを最小限に抑えることができます。単一のはんだボールを選択的に吐出する機構のため、はんだ付けにマスキングのためのツールが必要とされず、柔軟かつ非接触でのはんだ付けを可能にします。

- フラックスレス

- マスク・ステンシル不要

- クリーン

- 高いはんだ付け精度

- 低熱ストレス

- 3Dはんだ付け可

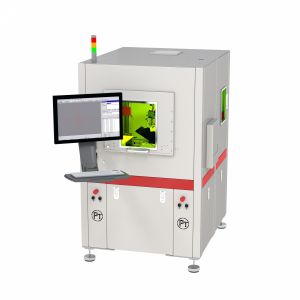

局所的なレーザー加熱機構により基板全体をリフロー温度まで加熱することなく、目的の配線部分に選択的に温度をかけ、リフローすることができます。カスタマイズされたボンドツールとレーザー技術を用い、ピック&プレースからレーザーリフローまでを高精度かつワンステップで実現します。大型チップから300μmのような超小型チップのアセンブリをサポートします。

また、独自の温度制御機構により、チップや部品の過加熱、基板の反りなどを防止します。

- レーザーによる局所的・選択的なリフロー

- 柔軟なレーザービーム形状

- 低熱ストレスの常温プロセス

- カスタマイズ可能なボンドツール

- 高い位置精度

- CTEミスマッチのある材料の接合に適している

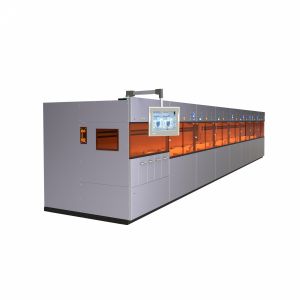

Ultra-SB²は、フラックス印刷 / ボールマウンタ / 2D検査 / リフロー前リワークを統合した全自動はんだボールマウンタで、バンプ収率を最大100%まで実現します。カセットからカセットへのウェーハ搬送が可能で、統合された2D検査は、ボール搭載後のウェーハだけでなく、ボール搭載前後のステンシル検査も含み、はんだバンプ工程管理を最大化することができます。

微細なはんだボールやファインピッチのレイアウトに対しても、高精度なボールマウントが可能です。はんだボールを搭載したウェハは、はんだボールの欠落、位置ずれ、余分なはんだボールがないかなどを再度検査されます。リジェクト品は、リフロー工程の前にリワークプロセスで処理されます。また、Ultra-SB2はカスタマイズが可能で、既存の製造ラインに別のウェーハハンドリングシステムを介して組み込むことで、インライン化を実現します。

- 4″~12 “ウェーハ対応

- FOUPからFOUPへの自動ローディング/アンローディング

- リワーク機能により、バンプの歩留まりを最大化

- 高精度

- 統合されたフラックスプリントと2D AOI

- インライン化対応可能

当社の無電解めっきプロセスは、シリコン、シリコン化合物、リン化インジウム、タンタル酸リチウムなどの様々な素材の半導体ウェーハを対象とし、ウェーハ上のAlやCuなどのボンドパッドの上にNi、Pd、Auなどのめっきを形成します。これらはフリップチップやWLCSPなどの各種パッケージの信頼性と性能を高めるために、はんだやワイヤボンドの接着層、拡散バリアー層、はんだ濡れ性向上などの機能を果たします。

装置に加えて、25年以上にわたる自社でのWLPサービスの量産経験から、再現性と信頼性の高い結果を得るための独自のめっき薬液も取り揃えています。

ウェーハは、完全自動化されためっきラインに投入されます。ロボットハンドラーによってウェーハはライン内を搬送され、インライン分析とメンテナンスによって十分に管理された薬液槽を通過します。

委託加工サービスや装置/薬品の販売だけでなく技術移転/トレーニングも含め、委託での少量生産からお客様工場内でのめっきライン導入に至るまでをフルサポートする、独自のターンキーモデルを提供しています。

低コストかつ高い生産性

- マスクレスのめっきプロセス

- 完全自動されたドライイン・ドライアウトプロセス

4 ” – 12 “のウェーハに対応

インラインのめっき液分析とめっき槽メンテナンス

マルチレシピ管理、SECS GEMインターフェース対応